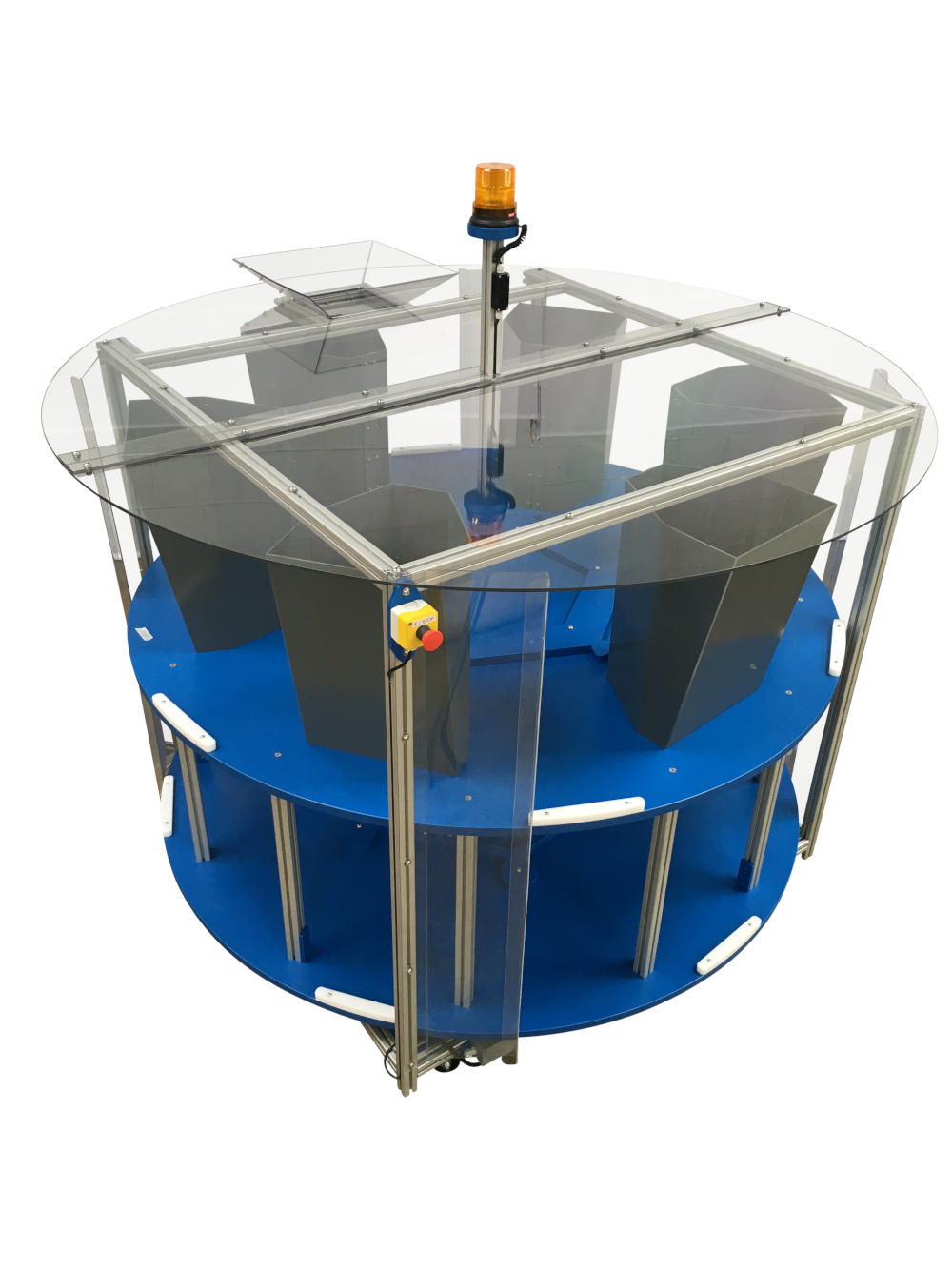

The Rotary Table Box Filling Carousel manufactured by ST Machinery is a versatile and efficient system designed to streamline the box filling process with precision and reliability.

With three standard sizes available, it caters to various production needs while featuring a durable PE500 base for long-lasting performance. Operating on single-phase power, it offers convenience and ease of integration into existing setups.

This box filling carousel is equipped with advanced automation features to optimize workflow and enhance productivity:

- Upon box filling completion, a stop signal is transmitted to the conveyor, triggering a custom set conveyor run time.

- This ensures that any remaining product clears the conveyor before another custom set timer halts the conveyor while the table rotates to the next box position.

- During this brief conveyor stoppage, the count signal from the Injection Molding Machine (IMM) continues to accumulate for the next box to be filled, maintaining seamless production flow.

- This intelligent system ensures efficient operation, precise product handling, and seamless coordination between the carousel and conveyor, ultimately improving overall production efficiency and output quality.

Standard features of our Rotary Table Box Filling Carousel:

- Easy setup with a Mitsubishi HMI Screen

- Up to 12 box filling positions

- Program interruption (replace filled boxes halfway through cycle)

- Variable box quantities if different box sizes are needed

- Part counting via machine signal

- Adjustable conveyor stop time (during carousel move)

- Efficient 100W single-phase motor

- E-stop on control box (built-in Omron e-stop system)

- Mitsubishi PLC

- 100v – 240v input

Multiple options available to meet your requirements :

- Bespoke table sizes

- Bespoke loading conveyor

- Siren and beacon

- Part counting via sensor detection

- Weigh Hopper

- Box Locators

- Double Tier

- Clear Safety Covers

- Full line integration with Mitsubishi PLC

- Additional e-stops, including machine integration