ST Machinery conveyor solutions case studies.

Conveyor Ancilliaries

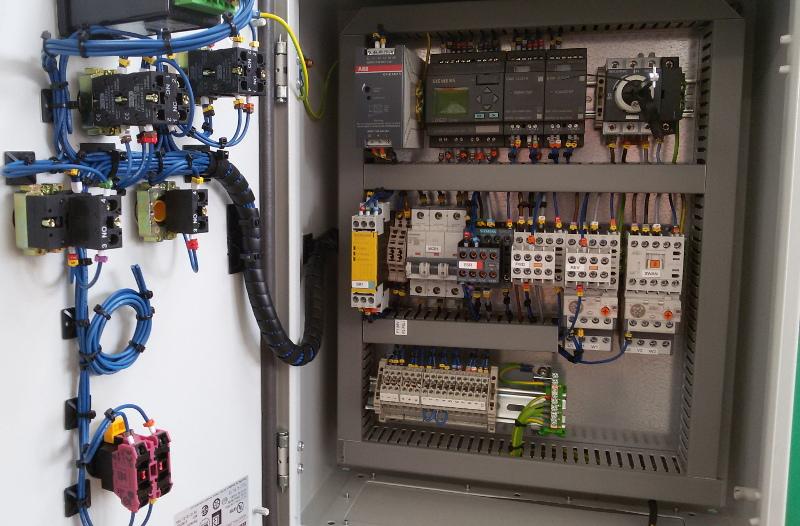

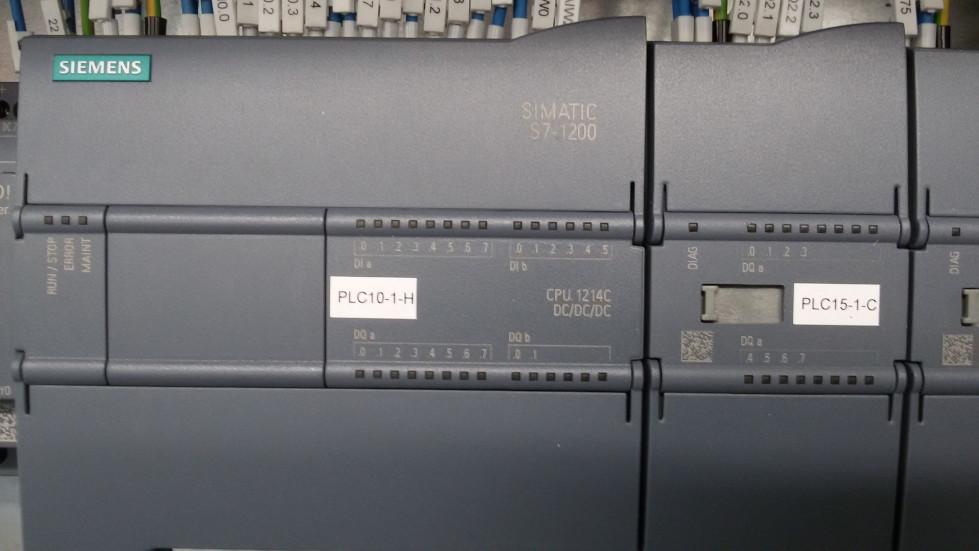

Conveyors designed to incorporate a wide variety of control systems

ST Machinery's conveyors are designed to easily incorporate a wide variety of Control Systems, tailored to suit production process requirements.

Conveyor Control Systems, from simple stop/start, forward/reverse to fully integrated automation control systems.

Feel free to Call Chris on 01933 271829 and have a chat about your automation control requirements when considering the integration of a conveyor system with your existing machinery.

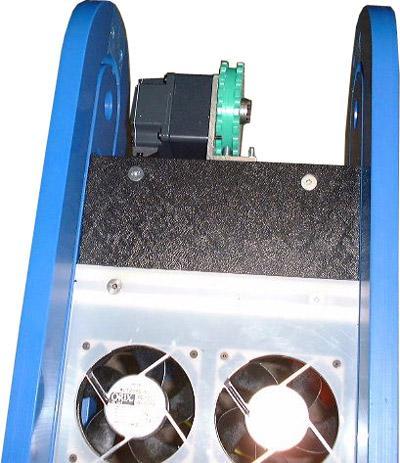

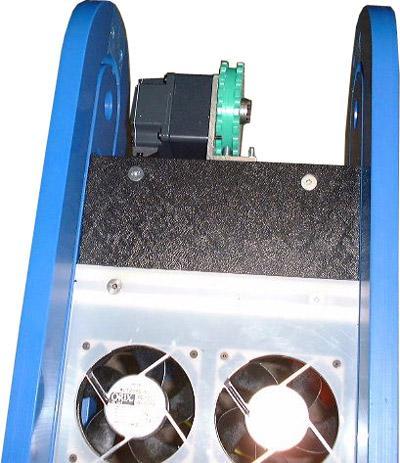

Plastic modular conveyors manufactured by ST Machinery can be designed to incorporate cooling fans, which are neatly housed underneath the conveyor belt surface.

Typically used in the plastic moulding industry, conveyors with integral cooling fans allow rapid cooling of plastic components prior to arrival at the next manufacturing process.

Cooling conveyors are tailor designed to suit customer application requirements with attention to the number, size and speed of the cooling fans along with speed control of the conveyor itself.

Cooling Conveyors offer a highly effective solution for product cooling control through 22% open mesh belt, and are available with a wide range of options for varying conveyor belt widths and lengths.

Select 'cooling fans' in the ancilliaries section of the conveyor enquiry form and we will contact you to discuss your exact cooling requirements during the quotation phase.

For precise product quantity control all models of ST conveyors can be designed to incorporate Weigh Scales.

Weighing scales offer a highly effective solution for product quantity control.

Weigh Scale Conveyors are tailor designed to suit customer application requirements.

The Weigh Scales are easily setup which will auto conveyor stop when weight target is reached with siren and beacon alert.

Available in a range of sizes for varying conveyor belt widths.

Select 'Weighing scales' in the ancillaries section of the conveyor enquiry form and we will contact you to discuss your exact requirements during the quotation phase.

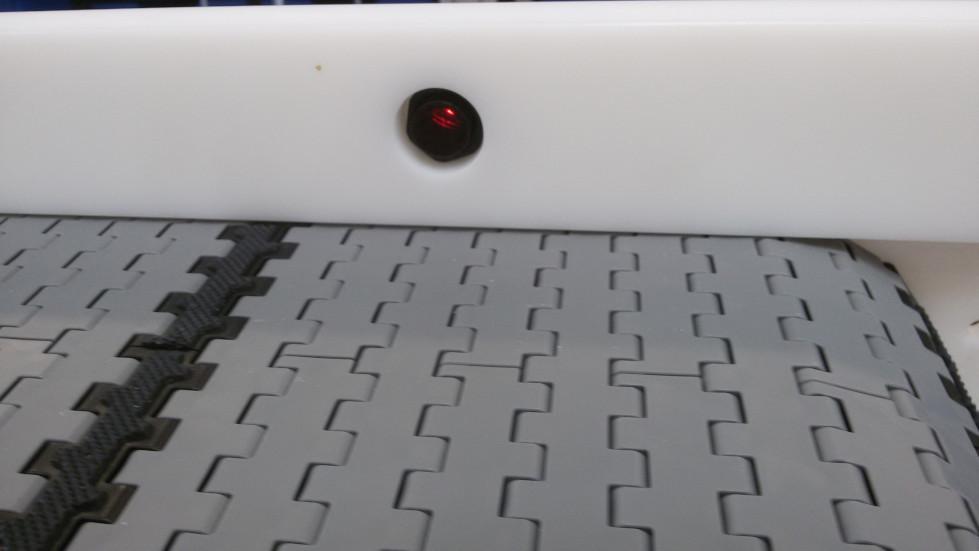

ST Machinery plastic conveyors can incorporate Tunnel Metal Detectors, offering precise metal detection to prevent product contamination or potential damage to other machinery.

The type of Tunnel Metal Detector fitted to the modular plastic conveyor is tailor designed to suit customer application requirements.

Typically metal particle detection as small as 0.5mm in both ferrous and non-ferrous metals is possible.

Tunnel Metal Detectors are widely used on conveyors in the medical, food and plastics industries for small particle detection.

Conveyors fitted with metal detectors automatically stop on contamination detection, along with siren and beacon alerts.

Tunnel metal detectors are available in a wide range of sizes for varying conveyor belt widths.

When filling the conveyor enquiry form select 'Tunnel metal detection' under the ancilleries group and we will discuss the range of options available, other ancillaries may also be selected by using the Ctrl key on your keyboard.