Separating plastic sprues from moulded plastic products is a task faced by every plastics manufacturer.

The sprue separators manufactured by ST Machinery are a product of our 20+ year experience of working closely with the plastics industry to develop solutions that are reliable and cost effective.

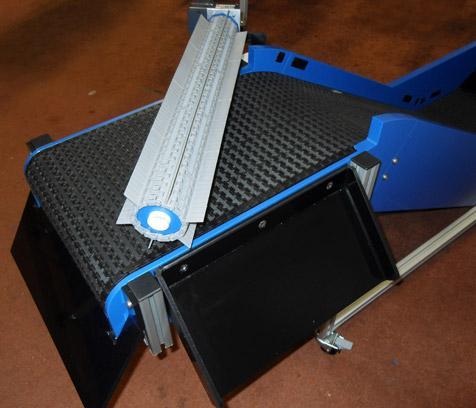

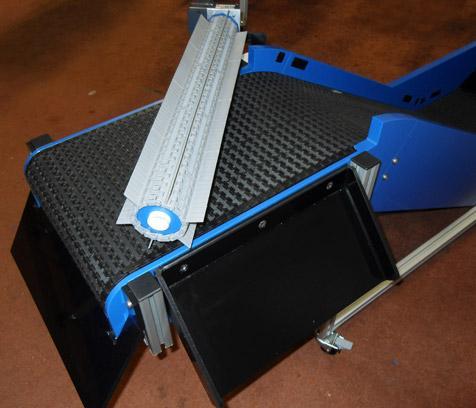

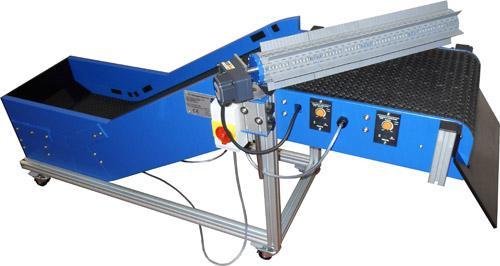

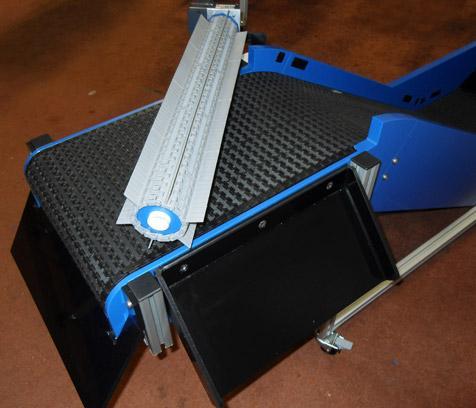

Our Roller Sprue Separators and Paddle Sprue Separators are tailor designed to integrate with any ST Machinery modular conveyor or other conveyor for control of your product sorting and separating requirements.

All our automated sprue separator solutions can be designed to complement your existing conveyor system.

For separating moulded plastic parts from their sprues, ST Machinery offer Paddle Separators in a variety of widths and colours individually designed to meet application and space requirements.

Paddle Separator Conveyors are the ideal solution for large component part from sprue separation into separate boxes.

Available as stand-alone units or integrated with conveyors to meet process requirements.

Part sprue paddle separator conveyors can be designed with multiple paddles for multiple parts from sprue separation.

Will it work for you?

We will video and come back to you with the results.

Click here to download separator test form

Why compromise on standard Paddle Separator Conveyors when we can design and build you a bespoke conveyor system for your exact requirements at comparable costs.

- Variable speed single phase motors.

- High strength low friction HM Polyethylene PE500 side frames are chemically inert with no corrosion.

- Machined side frames keep the belt under control and prevents side to side movement, a potential problem with conventional belt conveyors.

- Low running costs and minimal maintenance.

- The modular rubber grip top belt can be completely removed from a conveyor in less than 2 minutes for easy cleaning.

- Option of castors or foot mounted.

Part runner sprue separator conveyors side frames are mounted in an anodised aluminium section to give a solid and robust structure for years of use.

{ BreezingForms : paddle_sprue_separators }

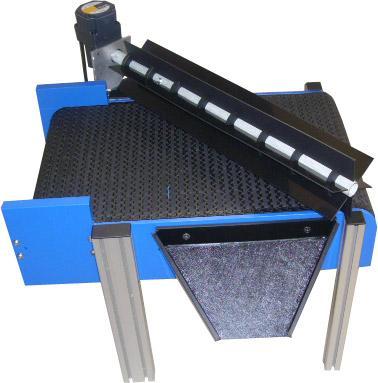

ST Machinery Roller Sprue Separators, are the ideal solution for separating moulded plastic component parts from sprue and discharging into separate boxes.

Tailor designed and manufactured in Northamptonshire UK to suit varying conveyor sizes as stand alone units for use under multiple conveyors.

Large twin Sprue Separator Rollers 108 mm diameter give the best separation of very small component parts from sprues with a size differential from 0 to 50mm.

Sprue separators can be free standing single units or used in tandem.

Will it work for you?

We will video and come back to you with the results.

Click here to download separator test form

- Spiral grooves with axial grooves for part / sprue discharge and agitation.

- Easy roller adjustment with large auto adjusting collection chutes.

- Efficient 20 watt internally mounted variable speed single phase motor for discharge and agitation control.

- Virtually maintenance free with no lubrication required.

- Height adjustable or built to custom height.

- Choice of colours.

{ BreezingForms : roller_sprue_separators }