Modular Plastic Conveyors UK Designed And Manufactured

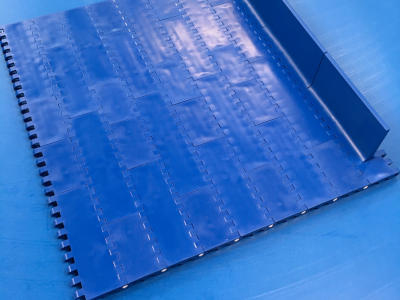

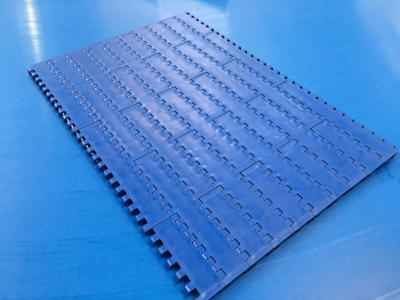

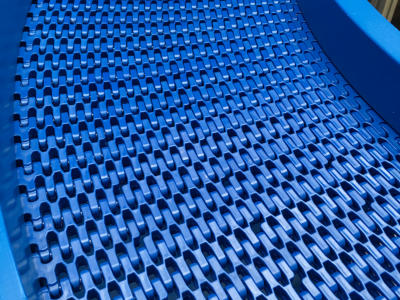

Modular Belt Types and Options

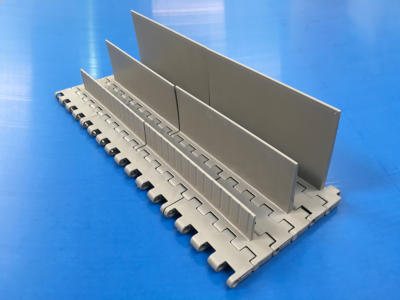

ST Machinery Conveyors are offered with a wide variety of modular plastic belt choices to suit application needs.

Differing plastic belt styles, FDA food grade materials and colours are available in addition to a variety of product support flights in differing heights.

- 19.1mm pitch – A straight running modular belt available with a closed or open area up to 22%.

Widths start from 76mm in increments of 76mm. Product flight supports available in 25mm, 50mm and 75mm height.

Standard materials are Polypropylene whilst Nylon can be used for high temperature applications. Also available in rubber grip top.

- 25.4mm pitch – A straight running closed top modular belt available in widths from 76mm in increments of 76mm.

Product flight supports available in 25mm, 50mm and 75mm height. Standard materials are Polypropylene and Acetal.

- 50.8mm pitch – A very strong straight running closed modular belt for heavy duty conveying applications.

Available in widths from 151mm in varying increments up to 2512mm wide.

Product flight supports available from 25mm to 150mm in height.

Standard materials are Polypropylene and PE whilst Acetal can be used for high temperature applications.

Also available in rubber grip top.

Roller Conveyors

Roller Conveyors Quality Made In The UK

ST Machinery manufacture Roller Conveyors offering infinitely variable lengths in a variety of widths and individually designed to meet application and space requirements.

There is a choice of Powered or Non Powered conveyors.

Powered Roller Conveyors can be straight or curved.

There are options for feeders, diverters and 90 degree transfers offering a modular system to suit application requirements available.

Load capacities up to 250 kg/m and speeds up to 2.0 m/s available.

Available with a wide variety of controls from simple stop / start to fully integrated systems.

Steel Rollers and Anodised aluminium side frames.

Non driven Roller Conveyors transport products manually or over a gradient via gravity and are ideal for assembly and picking lines.

Non driven Roller Conveyors can be straight or curved with options for the addition of ball tables to allow for products to be moved horizontally in any direction.

Load capacity up to 100 kg/m.

Plastic or Anodised aluminium side frames.

Plastic or steel rollers are available, in a variety of widths and diameters.

Curved Conveyors

ST Machinery manufacture low friction plastic Curved Conveyors

and offer infinitely variable lengths and shapes in a variety of widths and colours individually designed to meet application and space requirements.

Why compromise on a standard Curved Conveyor when we can design and build you a bespoke conveyor system for your exact requirements at comparable costs.

The curved conveyors feature a wide choice of side flexing modular conveyor belt and product support flights.

Variable speed single phase or 3 phase motors mounted internally within belt track.

High strength low friction HM Polyethylene PE500 side frames are chemically inert with no corrosion.

Machined side frames keep the belt under control and prevent side to side movement, a potential problem with conventional belt conveyors.

Low running costs and minimal maintenance.

The modular belt can be completely removed from a conveyor in less than 3 minutes for easy cleaning, adding or removing product support flights.

Curved Conveyor side frames are mounted in an anodised aluminium section to give a solid and robust structure for years of use.

Option of castors or foot mounted.

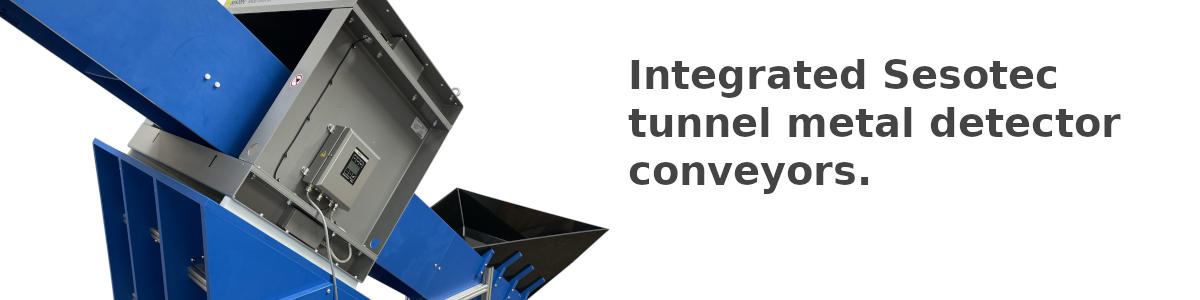

All ST Curved Conveyors can be supplied with a variety of ancillaries such as metal detectors, weigh scales, cooling fans and also with a variety of control systems from simple stop/start to fully integrated units.

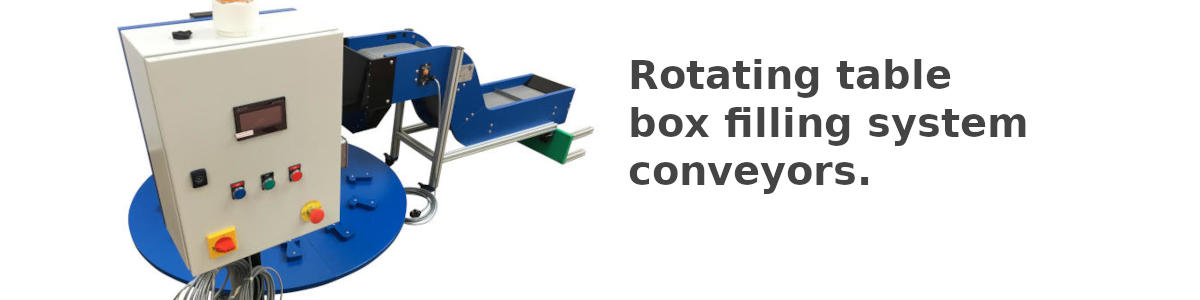

Curved Conveyors are available with complementary product handling equipment – Rotary Box Fillers, Roller Separators and Paddle Separators in matching colours designed for exact process requirements.

Swan Neck Conveyors

Modular Plastic Swan Neck Conveyors with Modular Plastic Belt

Swan Neck Conveyors are ideal for use with plastic injection and blow molding machines.

With fast turnaround from design to delivery, ST Machinery Ltd, a renowned UK manufacturer of conveyor systems, can build swan neck conveyors to your exact requirements at a comparable cost to 'off the shelf' lower quality conveyors.

Our patented low friction plastic conveyor design offers infinitely variable shapes, and sizes of Swan Neck Conveyors in a variety of widths and colours to produce a bespoke conveyor to meet any machine or process application.

Features:

- Wide choice of modular conveyor belt types and product support flights.

- Variable speed single phase or 3 phase motors mounted internally within the belt track.

- High strength, low friction HM Polyethylene PE500 side frames are chemically inert with no corrosion.

- Machined side frames keep the belt under control and prevent side to side movement, a potential problem with conventional belt conveyors.

- Low running costs and minimal maintenance.

- Option of castors or foot mounted.

The modular belt can be completely removed from a conveyor in less than 3 minutes for easy cleaning, adding or removing product support flights.

Swan Neck Conveyor side frames are mounted in anodised aluminium section to give a solid and robust structure for years of use.

All ST Swan Neck Conveyors can be supplied with a variety of ancillaries such as metal detectors, weigh scales, cooling fans and also with a variety of control systems from simple stop/start to fully integrated units.

Swan Neck Conveyors are available with complementary product handling equipment – Rotary Box Fillers, Roller Separators and Paddle Separators in matching colours designed for exact process requirements.